Click here to download a PDF outlining this project.

Client: CEESI CEESI.com

Location: CEESI Ventura High Flow Facility near Ventura, IA

Start Date: July 2019

Completion Date:

CEESI performs accredited traceable calibrations for a variety of types of flow meters using numerous types of fluids. CEESI also offers calibration-related engineering services, wet gas/multiphase testing, valve testing and flow measurement training.

CEESI is accredited to ISO/IEC 17025 for calibrations by the American Association for Laboratory Accreditation (A2LA).

https://www.ceesi.com/contact-us

The facility accesses up to 1 BCFD of gas from a midstream sales line for SI traceable calibration of meters from 3 inch to 36 inch with flowrate uncertainties of 0.18% to 0.44% (depending on flowrate).

Resolute was contracted to supply project management, electrical, mechanical, structural and process engineering services to provide:

- Operability enhancements to increase the number of meters calibrated per day, including an overhead bridge crane, rail transfer system and automation of isolation and purge valves.

- System improvements include nitrogen purge c/w operating procedures, upgraded instrument air package and upgraded gas re-compressor to inject calibration gas back into the sales line.

- Design an installation of upgraded electrical service and a new MCC/PDC skid.

- Construction management – on site and home office support.

- Overhead Bridge Crane to enhance material handling.

- Specify MCC/PDC and transformer:

- Procurement and material specification

- Electrical classification drawings, one line drawings, cable and conduit specification, layout and detail drawings

- Instrumentation and Electrical design for a new safety PLC, a new process PLC and gas and fire detection systems

- Process engineering, including Process and Instrumentation Diagram (P&ID), purge system for purging calibration test sections to nitrogen from gas, to nitrogen from air and from nitrogen to gas.

- Develop welding procedures

- Gap analysis for this party specifications against industry standards.

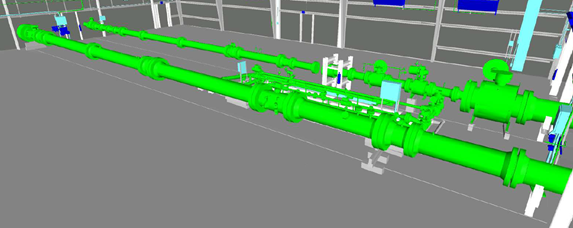

- The Resolute Engineering team leveraged their extensive operations engineering experience with a flexible approach to provide lean engineering solutions while generating minimal drawings to complete the various phases of the project. For example, Resolute created a 3D model from Trimble scan data to use as a design basis and for the creation of piping, electrical and structural drawings.

-

The Resolute Team used their operations experience to evaluate bulk liquid nitrogen (LIN) system (cryogenic) against a generated system nitrogen (electric drive air compressor, air dryer, nitrogen membrane and nitrogen gas accumulators) on a Life Cycle Cost basis. The LIN system was a clear choice and helped the client to defer capital cost in addition to improving NPV by $94,000. Resolute also recommended 1 inch 304 SS tubing with Swagelok fittings as an alternative to welded piping for a further savings of approximately $30,000.

Types of Projects

Types of Projects